welding technologies

In currents welding processes, we meet generaly: - Shielded Metal Arc Welding (SMAW), also named stick welding. - Gaz torch welding (also named oxy~fuel welding, oxy cutting). - TIG Welding also named Gaz Tungsten Arc Welding (GTAW). - Gaz Metal Arc Welding (GMAW).

Shielded Metal Arc Welding (SMAW)

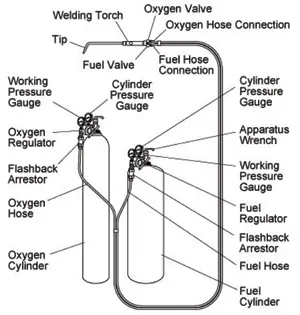

Gas Torch Welding (Oxy fuel welding)

Gas torch welding is a process for thermally joining sheets and tubes of the same material with a thickness of 2 mm or less. In fact, it is a mixture of two gases, oxygen and acetylene. This mixture ignites and, after correct adjustment, allows welding. The weld itself is obtained after the metal to be welded has been brought to fusion. The filler metal is then added to obtain a quality weld.

TIG Welding (GTAW)

Tig welding, like MIG welding, is obtained by the electric arc between the workpiece and the infusible tungsten electrode; the energy obtained allows the metal to be brought to fusion and the filler metal to be added manually.

How do TIG welding machines work?MIG/MAG Welding (GMAW)

MIG welding is a very popular process nowadays. For this process, an electric arc is obtained between the workpiece and the filler wire; when the arc is obtained, the filler wire is passed at a steady speed through the molten metal generated by the powerful energy of the arc. A weld bead is produced by mixing the filler metal and the molten base metal during melting, which is carried out under gas protection.

exhaustive list of welding processes. simple course on gases and their actions in welding.